|

产品详情

当前位置:

首页>

产品详情

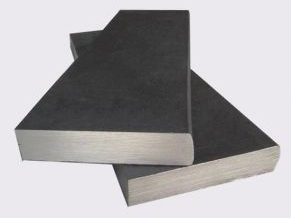

Invar 36

Invar36Invar36 is a special low-expansion iron-nickel alloy with ultra-low expansion coefficient. Among them, the control of carbon and manganese components is very important. Cold deformation can reduce the coefficient of thermal expansion, and heat treatment in a specific temperature range can stabilize the coefficient of thermal expansion. Chinese name:Invar36 Properties: Special low-expansion iron-nickel alloy Characteristics: good plasticity and toughness Similar grades: 4J36 (China), Fe-Ni36 (France) Characteristic●It has a very low thermal expansion coefficient between -250℃ and +200℃ Application fieldInvar 36 is used in environments that require extremely low expansion coefficients. Typical applications are as follows: ●Production, storage and transportation of liquefied gas ●Measurement and control instruments whose working temperature is lower than +200℃, such as temperature adjustment devices ●Screw connector bushing between metal and other materials ●Bimetal and temperature control bimetal ●Membrane frame ●Shadow Mask ●Aerospace industry's CRP parts tempering mold ●The frame of artificial satellite and missile electronic control unit below -200℃ ●The auxiliary tube in the electromagnetic lens of the laser control device

Similar grades4J36 (China), Fe-Ni36 (France), 1.3912, Ni36 (Germany), X1NiCrMoCu, N 25-20-7 (UK) Invar 36, UNSK93600 thermostat alloy, UNSK93601 pressure vessel sheet (USA)

Physical propertiesInvar36 density Density: ρ=8.1g/cm3 Invar36 melting temperature range Melting temperature range: 1430℃ Invar36 Curie temperature Curie temperature: 230 ℃ Invar36 specific heat Specific heat: 515J/Kg

WeldingInvar 36 can use all welding processes for welding, including tungsten electrode welding, metal arc welding, plasma welding, argon arc welding, manual arc welding, etc. First consider the use of pulsed arc welding. Before welding, the material should be in an annealed state, clean and free of oil, scratches, marking paint, etc. Low heat input must be used, and the interlayer temperature should be lower than 120°C. No pre-weld and post-weld heat treatment is required. Invar36 recommended welding materials If the weld performance is designed to be the same as that of the base metal, the welding rod of the same material as the base metal is required. Or choose Choose below GTAW/GMAW Nicrofer S 7020 W.-Nr.2.4806 SG-NiCr20Nb AWS A 5.14 ERNiCr-3 SMAW W.-Nr.2.4648 EL-NiCr19Nb AWS A 5.11 EniCrFe-3

下一页

|